Highly effective inhibitory water-based drilling fluid system for drilling active clay deposits. An environmentally and cost-effective alternative to a hydrocarbon-based solution.

An effective solution to such problems as well bottom tool failure, walls shedding, trunk narrowing, inability to lower the casing due to insufficient inhibition of drilling fluid, leading to an increase in the construction time of wells, a significant increase in the cost of work, and sometimes to the loss of the well.

Wellbore quality

-The possibility to drill the unstable claystones intervals without increasing the density

-Significant reduction of cavernosity

Drilling of active clays

-Significant reduction of clay production in drilling fluid (MВТ test)

-Reduction of packing formation chances

-Reduction of dilution of solutions/waste

Cementing quality

-Improvement of the cement bond acoustic log by achieving wellbore close to the nominal

Drilling fluid cost

-Cost-effective alternative to hydrocarbon-based solutions

-Reduction of costs for drilling fluid preparation

-Mixing with any type of water-based solutions

-No need to change the type of solution for different geological intervals

Requirements for cleaning equipment

-The possibility of using incomplete cycle solids control equipment or equipment with a low efficiency rate

Environmental safety

The high efficiency of clay inhibition and stability of the drilling fluid parameters of the system comparable in reliability to hydrocarbon-based solutions is achieved by the use of high-quality materials and a synergistic effect between sodium chloride salts and an organic FORTIHIB inhibitor and a polymer encapsulator.

Organic FORTIHIB Inhibitor

-Synergistic effect with sodium chloride;

-Suppresses the ability of clay to absorb water;

-Unlike KCL, it inhibits clays regardless of their mineralogical composition, including kaolinite;

-Does not introduce errors in the readings of geophysical instruments;

-Has an anti-corrosion effect.

Amine-type clay swelling inhibitor

Designed to inhibit hydration, swelling of clays and clay shales during drilling operations and well construction.

Advantages of application

– reduces the working time of clay production in drilling fluid (MВТ test);

– prevents the formation of cavities on the walls of the well;

– reduces the chances for packing formation;

– compatible with most water-based drilling mud systems.

Method of application

The product is delivered ready-made, no additional preparation is required before adding to the drilling fluid.

It is recommended to use in concentrations from 5 to 30 kg / m3 of drilling fluid.

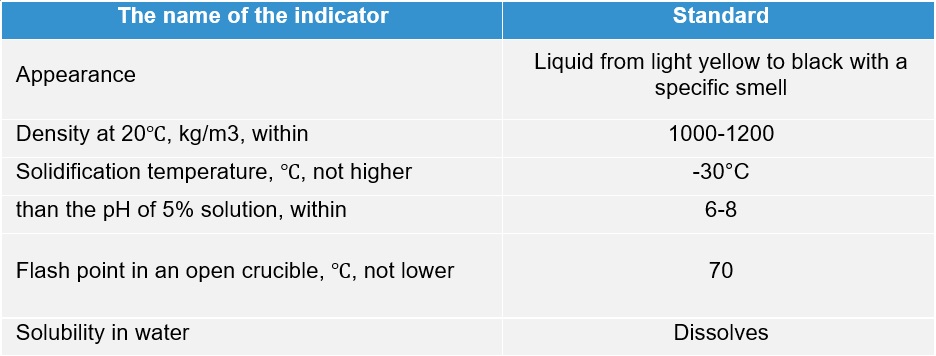

Technical specifications

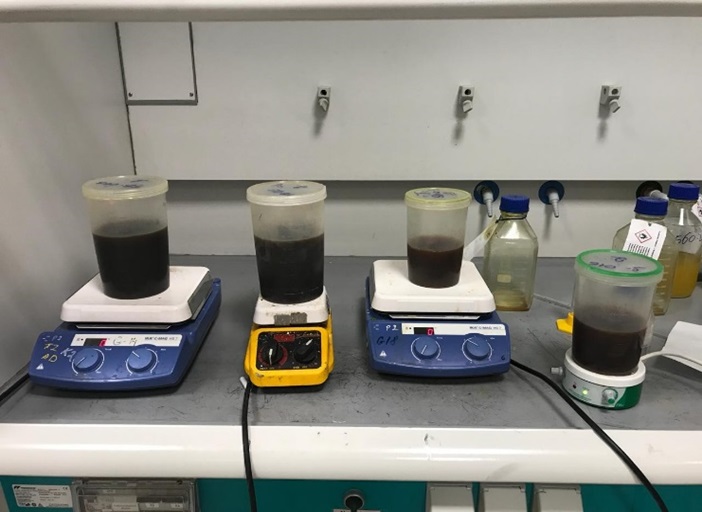

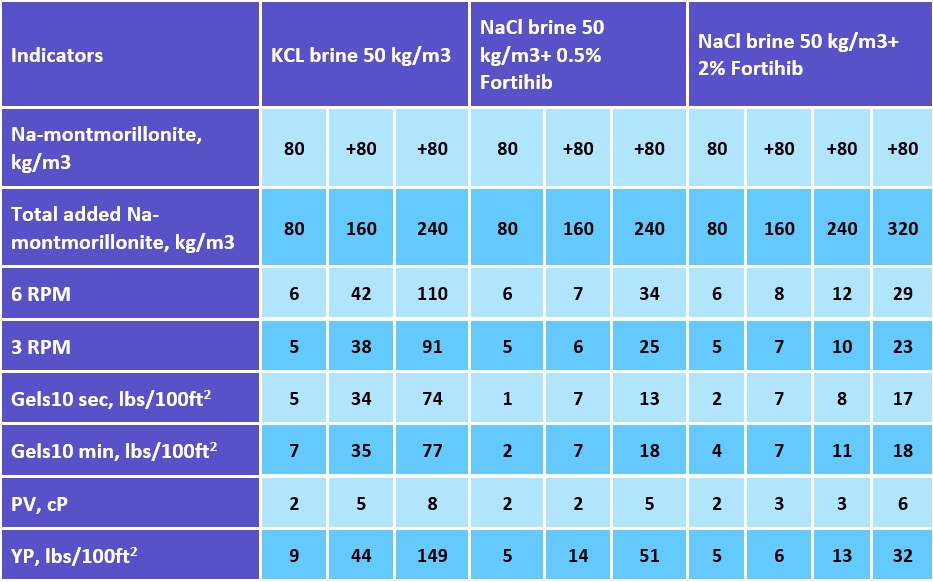

Evaluation of the effectiveness (conditional clay capacity) of the solution

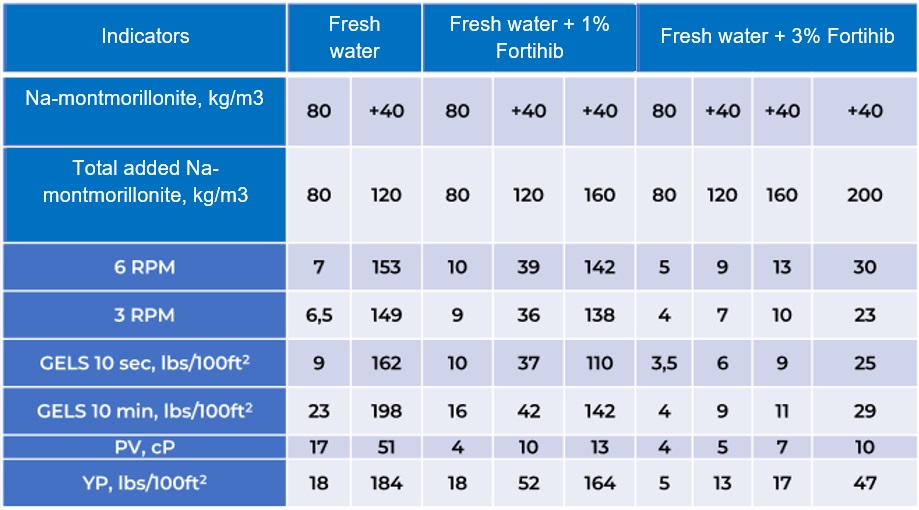

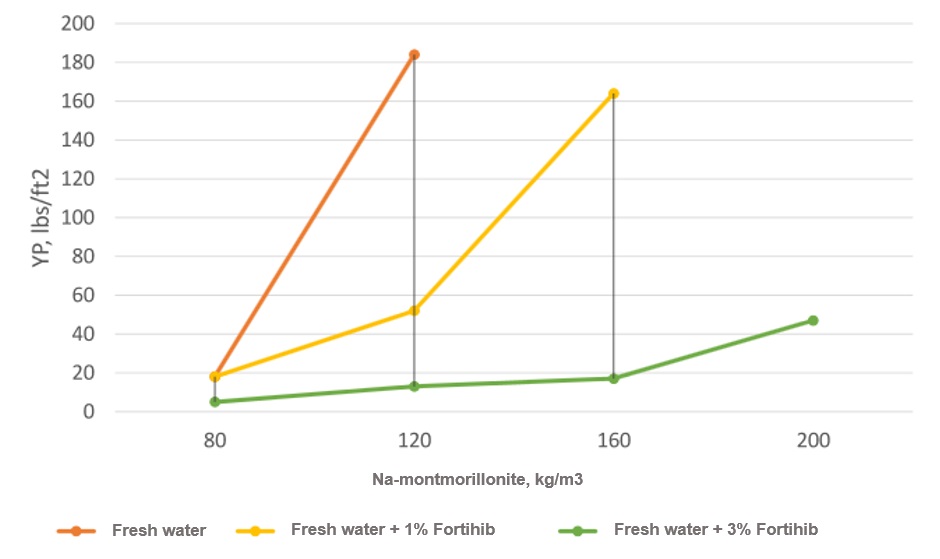

Change in the dynamic shear stress from the amount of montmorillonite mixed with the fresh solution

Laboratory tests and conclusions

The FORTIDRILL system is based on new FORTIHIB polyamine inhibitor.

As a result of numerous laboratory analyses and comparisons with existing drilling fluid systems, as well as new developments of leading Western companies the FORTIDRILL system proved the following:

– a high clay capacity;

– can be used in fresh and

highly mineralized systems;

surpasses the KCL/polymer system in many respects;

– the efficiency is comparable to a hydrocarbon-based solution

Conducted research

Influence on the properties of solutions

Investigation of the preservation of clay granules

General strength test

Packing formation

Linear swelling

Determination of the maximum clay capacity

Anticorrosive properties

To activate the inhibitory properties of the system, the content of chlorides is necessary, and it does not matter which chlorides of salts will be used. In this case, the system significantly benefits in cost, as it allows the use of sodium chloride salt without resorting to the use of expensive and scarce potassium chloride salt.

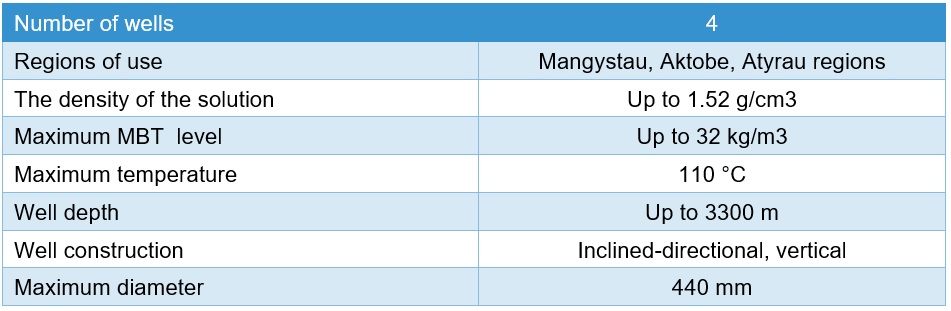

Application experience